All About A/c Leak Fix

The machine is reduced and requires recharging if both the low and high side pressure gauges read low. But before any toaster is added, check to find out where the refrigerant is going. AIR CONDITIONING PROBLEM: REFRIGERANT LEAKS All vehicles flow microscopic and some refrigerant seals pores .

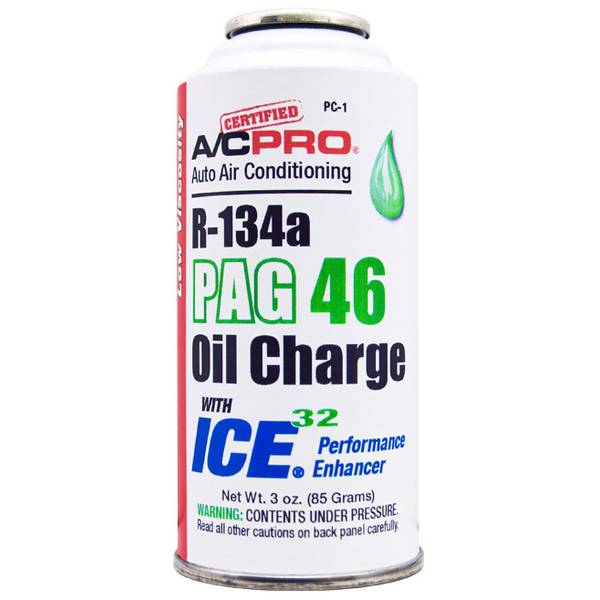

The telltale oil spots and wet stains that indicate leaks on older R-12 systems are less noticeable on the newer R-134a systems since PAG lubricants are not as"oily" as mineral oil. This makes it more challenging to observe leaks. Leaks can be located with the addition of special dye into the system (accessible pressurized cans caked with refrigerant), an electronic leak detector, or plain old soapy water (spray on hose connections and watch for bubbles -- requires adding some equipment to procedure initially and turning off the A/C on).

Most leak repairs require replacing seals O-rings or hoses. But if the evaporator or condenser are leaking, repairs can be costly. POOR COOLING PERFORMANCE Diagnosing an A/C cooling problem is best achieved by linking a judge set to the high and low pressure service matching on the computer system. Though poor cooling is frequently because of a minimal charge of refrigerant, it can also be brought on by a number of other variables (see graph above).

The Buzz on A/c Leak Fix

Within an 80 degree day, the very low judge must read about 56 psi or higher if the A/C system contains an adequate charge of refrigerant. On a 90 degree day, the LOW negative studying ought to be higher or about 70 psi. The A/C system probably requires some refrigerant if the LOW estimate reading is much less than this.

_4.png)

An A/C system should comprise less than 2% atmosphere by weight. For every 1% increase in the amount of air that displaces refrigerant from the system, there'll be a corresponding drop of roughly a degree in cooling performance.

Stop Refrigerant Leaks Things To Know Before You Get This

On some equipment, this can be done. But on gear that lacks an automated purge cycle, tank pressure and temperature needs to be measured and compared to some static pressure reference chart. Air can be detected by some Read Full Report identifier gear . An identifier should be utilized to inspect the refrigerant until the machine is serviced to stop cross-contamination of recovery and recycling equipment.

This switch prevents the compressor from running if the refrigerant level is low. It can stop the compressor from arriving on if the cutout switch isn't reading correctly. Faulty compressor clutch. The clutch on the compressor requires complete battery voltage. In case the voltage into the clutch is low, or the clutch coils have an excessive amount of immunity, or even the air gap at the clutch is really great, the clutch might not engage to drive the compressor.

Check to find out if the relay is receiving voltage once the A/C is turned on. Check the and ground relations. The relay is bad if navigation battery voltage directly or bypassing the cable with a jumper wire makes the A/C function. Faulty A/C controller switch.

Some probable causes of intermittent cooling (or no heating ) on automatic A/C methods include each of the above, also:A problem in the management module or control mind (this generally requires using a dealer scan tool to read error codes and perform self-diagnostics). A terrible temperature detector (an ambient air temperature website link sensor, inside air temperature detector, evaporator temperature sensor, or sunload sensor).

10 Easy Facts About Stop Refrigerant Leaks Shown

AIR CONDITIONING PROBLEM: NOISE Noise from the compressor means the compressor is on its way out. But sound may also be caused by cross-contaminated refrigerant (operating pressure too large ), air from the machine or the wrong type of compressor lubricant. Noise can be caused by hoses or parts discriminated against other components in the engine compartment.